FROM CONCEPT TO CREATION

![]()

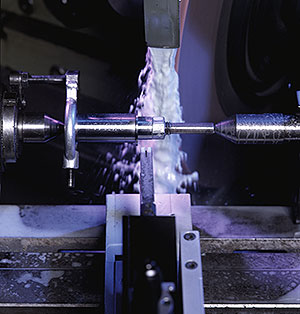

Accurate has the capacity to handle parts manufactured from bar stock, castings or forgings. We are familiar with alloy steels, stainless steels, nickel alloys, aluminum, and titanium. We will handle the entire job or spot manufaturing to customer instructions. Our facility is ideal for cylindrical parts up to 30 inches long and 6 inches in diameter. Accurate has established long term relationships with NADCAP approved processing facilities in areas such as heat treating, mag inspection/NDT, plating, etc.

Accurate Grinding & Manufacturing Corporation was established in 1950. We specialize in the manufacturing of close tolerance aerospace type components under the cerification of AS9100D. Our 30,000 square foot facility employs 50 people; 35 are directly involved in manufacturing. We maintain a complete machine shop, grinding facility, and full time inspection department. Our Statistical Process Control is established and running at Accurate. Customers are encouraged to highlight Key Characteristics to be controlled by the SPC procedures. SPC data is collected at a main SPC Computer Collection Center on the shop floor. The SPC Collection Center is operated by a full time SPC Specialist who is in contact with the manufacturing, Quality Control and Upper Management areas of Accurate. The SPC Specialist reports directly to the top management of the corporation.

Accurate Grinding & Manufacturing Corporation was established in 1950. We specialize in the manufacturing of close tolerance aerospace type components under the cerification of AS9100D. Our 30,000 square foot facility employs 50 people; 35 are directly involved in manufacturing. We maintain a complete machine shop, grinding facility, and full time inspection department. Our Statistical Process Control is established and running at Accurate. Customers are encouraged to highlight Key Characteristics to be controlled by the SPC procedures. SPC data is collected at a main SPC Computer Collection Center on the shop floor. The SPC Collection Center is operated by a full time SPC Specialist who is in contact with the manufacturing, Quality Control and Upper Management areas of Accurate. The SPC Specialist reports directly to the top management of the corporation.

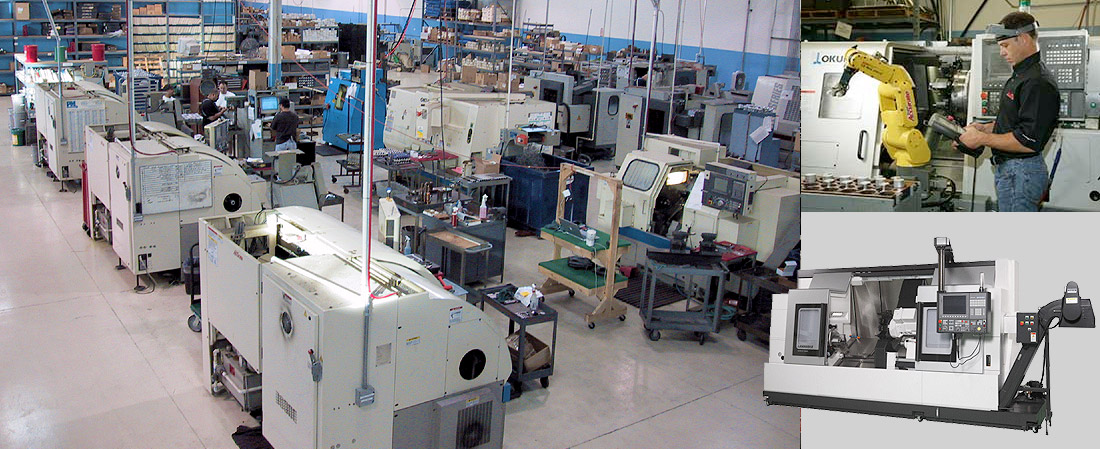

MACHINING SERVICES

![]()

(4) OKUMA, Crown – Bar Feed, Chucking

& Colleting(ID & OD)

(1) OKUMA LU-15 – Twin Turret Lathe

(1) OKUMA Captain L370MW, w/ Fanuc Robot and Conveyor- Twin Spindle , 8 Live tools

(1) Omni-Turn Lathe

(1) Okuma LB3000 Lathe w/ Fanuc Robot & Live Tools

(1) Okuma LB3000 Lathe w/4ft Barfeeder & Live Tools

Accurate Manufacturing has complete line of CNC Horizontal Milling Centers with Multi-Pallets and Vertical CNC Mills. These machines are tooled up for quick setups and high production milling. Most jobs have a 10 max minute setup time (after initial setup, programming and tooling has been completed).

(1) Okuma MB 4000 218 Tools, 2 Pallet Horizontal

(1) Okuma MA 400 154 Tools, 10 Pallet Horizontal

(1) Okuma Genos 560 Verical 40×20, 32 Tools

(1) Haas VF0 with 4th Axis w/4 Heads

(4) Haas 4th Axis Rotary Tables

(1) Haas 5th Axis Rotary Table

(1) CNC Cylindrical OD Grinder – Okuma

(1) Cylindrical OD Grinder – Tschudin

(3) Cylindrical OD Grinder Brown & Sharp

(2) Cylindrical ID Grinder – Cincinnati Milacron, Heald

(1) Cylindrical ID Grinder – Parker

(1) Surface Grinder – Okamoto

(3) Surface Grinder – Harig

(4) Engine Lathes

(2) Vertical Mills – Bridgeport

(1) Four Bank Drill Press Set –

(1) Automatic Saw – Amada

(1) Hone – Sunnen

Laser engrave marking on parts per customer requirements. Laser engraving has proved to be a great asset to providing quality part marking to our customers. We can import almost any graphic file or logo and engrave on the part and serialize.

Laser engrave marking on parts per customer requirements. Laser engraving has proved to be a great asset to providing quality part marking to our customers. We can import almost any graphic file or logo and engrave on the part and serialize.

Accurate’s own Custom Shop Management Program with wireless SYMBOL Pocket PC’s. We have developed our own programming to completely manage the production from sawing bar stock to First Article Inspections to shipping. This system is very flexible and has the ability to allow us to meet our customers on time delivery schedules because it is programming based on how we produce parts.

Pro/Engineer CAD solid moduling CEO 3

MasterCam X8

Dynamic Balancing